Double-Sided Adhesive Tape for Hair Extensions: Production, Market Demand, and Popularity Among Caucasian Women

Double-Sided Adhesive Tape for Hair Extensions: Production, Market Demand, and Popularity Among Caucasian Women

Double-sided adhesive tape for hair extensions is an essential tool in the beauty industry, providing a quick, easy, and non-damaging method to attach extensions. This article focuses on the production process, market demand, and the popularity of tape-in extensions among Caucasian women.

Production Process of Double-Sided Adhesive Tape

The production of double-sided adhesive tape for hair extensions requires precision to ensure durability, flexibility, and ease of use. The process typically involves several key steps:

Material Selection: High-quality materials are chosen to ensure that the tape is both lightweight and strong. The adhesive must be medical-grade to ensure it is safe for use on the scalp and does not cause irritation or damage to natural hair.

Adhesive Application: A thin, even layer of adhesive is applied to both sides of the tape. The adhesive must be strong enough to hold the extension securely for several weeks but gentle enough to be easily removed without leaving residue.

Cutting and Packaging: After the adhesive is applied, the tape is cut into strips that match the size of hair extension wefts. These strips are then packaged for easy application, often in pre-cut sections for consumer convenience.

Quality Control: Each batch of adhesive tape undergoes rigorous testing to ensure it meets safety and performance standards. The tape is tested for its hold, flexibility, and resistance to environmental factors such as humidity and heat.

Market Demand for Double-Sided Adhesive Tape

The demand for double-sided adhesive tape in the hair extension market has grown significantly. This growth is driven by several factors:

Increasing Popularity of Hair Extensions: As hair extensions become more mainstream, more women are looking for convenient, non-permanent solutions. Tape-in extensions, in particular, are favored for their ease of application and natural appearance, leading to a higher demand for high-quality adhesive tapes.

DIY Market: With the rise of do-it-yourself beauty products, many consumers prefer to apply hair extensions at home. This trend has boosted the demand for easy-to-use double-sided adhesive tapes, allowing users to achieve professional-looking results without visiting a salon.

Advancements in Adhesive Technology: The development of stronger, more durable tapes has expanded the market. Many manufacturers now offer tapes with varying strengths and materials, allowing users to choose a product that fits their specific hair type and styling needs.

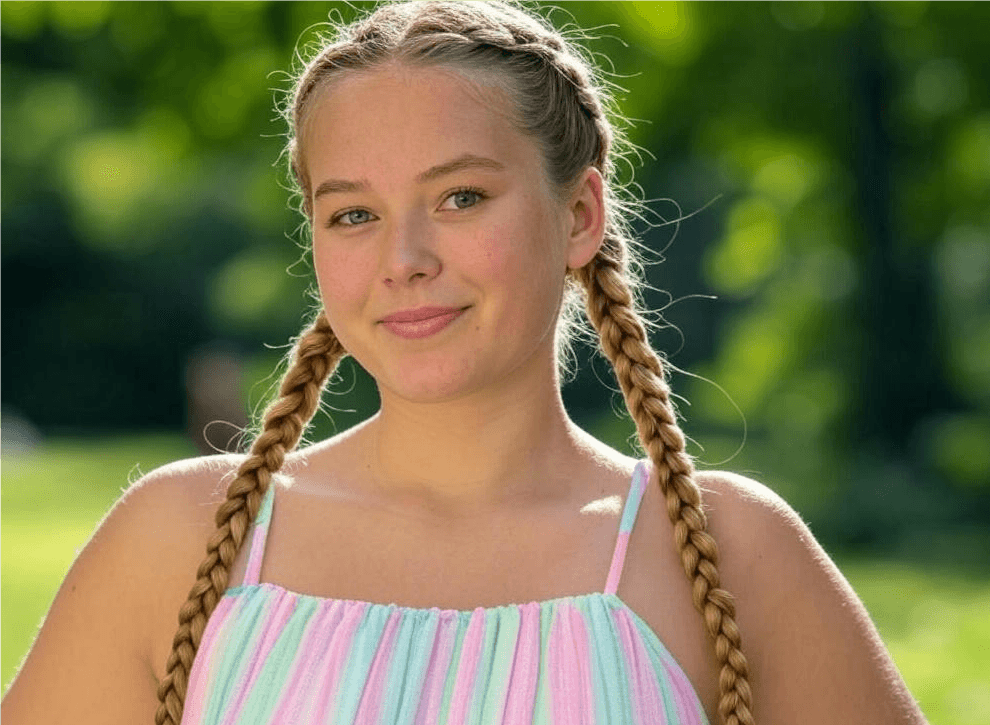

Popularity Among Caucasian Women

Caucasian women are one of the largest consumer groups for tape-in hair extensions, with double-sided adhesive tape being a key component in their beauty routines. Here’s why:

Versatility in Hairstyles: Tape-in extensions provide volume and length while blending seamlessly with natural hair. Caucasian women often prefer these extensions for their versatility, allowing them to achieve a range of hairstyles from sleek, straight looks to voluminous curls.

Natural Look: Double-sided adhesive tape allows the extensions to lie flat against the scalp, creating a natural look. This is particularly important for women with fine or thin hair, as the tape is discreet and nearly invisible.

Low Maintenance: Caucasian women appreciate the low-maintenance nature of tape-in extensions. With proper care, the extensions can last for up to 6-8 weeks, making them an attractive option for those seeking a long-lasting solution without frequent salon visits.

Conclusion

Double-sided adhesive tape for hair extensions plays a crucial role in the beauty industry, particularly among Caucasian women who value its natural appearance and ease of use. As the market for tape-in extensions continues to grow, advancements in adhesive technology and production processes are meeting the rising demand for high-quality, durable products.